1 Define hull layout=The structural arrangement from keel to deck is called hull layout.

2. Describe the procedure of hull layout=

(a) kell block setting

(b)kell & bottom construction

(c)Shell plating construction

(d) Deck plating

(e)BHD & pillar construction

(f) Fore end construction

(g) After end construction

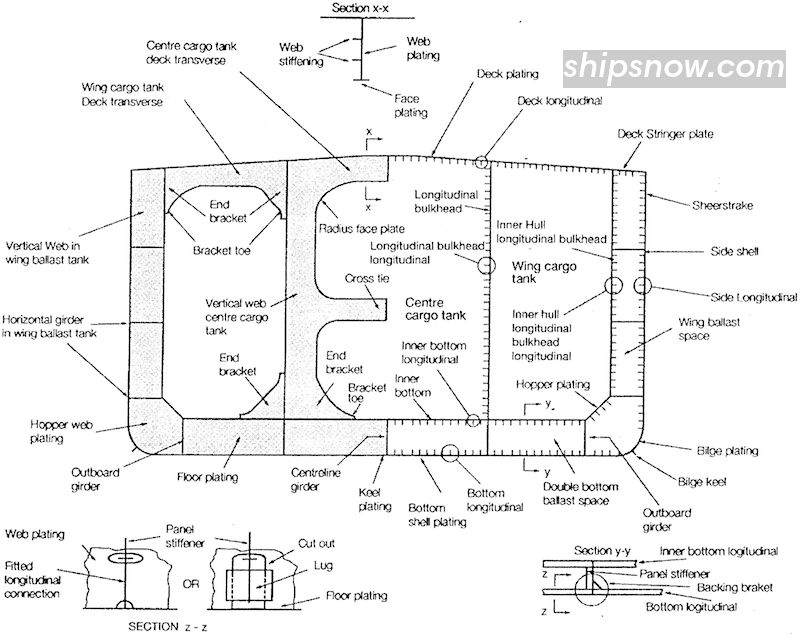

3. Describe welded construction of bottom plate=In ships with bottom plating of a ship within 0,4,L a ships a number longitudinal bottom stiffener depending on the breath of the vessel are to be fitted

4. Describe engine setting =The main engine setting above the inner bottom is to be supported by transverse brackets fitted over the floors. Longitudinal girders between bottom engine bedplate are to be constructed as continuous girder.

5. Identify hatch cover=when the tweendeck height exceeds 2,6 meters the thickness of the cover is to be increased by 10 mm for every 1 mm excess in twin deck height.

6. Identify hatch way beams=Scantlings of hatchway beams are to be determined in relation to their length and spacing.

7. Describe construction of hatch coaming=The thickness coaming plates or within in tact superstructure is not.

8. Identify fore castle deck beams= Forecastle and upper deck beams within 0,12Lfrom the stem are to be determined. From the calculate modulus is to be increased by 1,1ccc coefficient as given

9. Classify deck of a ship=various type of deck. They are as follows:-Berth, Boat, Boiler, Briedge, Main, Poop, Quarter, Side, Upper, Weather, Middle or Waisd, Flush deck..

10. Identify bar stem=It is solid round or rectangular bar. It consists of forged steel or cast steel. It is fitted form the keel to the upper must deck.

11. Mention the used of plate stem=it is provided vertical stiffener on the center line. It is coverd around sheel plate T=0.05L+4 in mm.

12. Mention the used of stern frames=To reduce serious vibration at after end, To provide a support for the rudder post, To provide the rudder pindle.

13. Describe scantling of floor plate= Floor plate are two have scantling determined from the following formula (a)depth of floor H=1.35ATB^+200 in mm when h=<500 mm. Here A=frame spacing. T=draft B=Breadth. (b) Tickness of floor T=0.52B+3.5 in mm the scantling of the flange of the floor to be determine the following formula T=o.o7L+5.2 in mm L=Length of a ship, B=L+50 in mm.

14. Describe center keelson=A vertical plate on the keel plate in center line running on the steam to stern. Which is increase is the longitudinal strength and tedious the longitudinal bending this plate called center keelson. It may be T or L section.

15. Describe the side keelson=A vertical plate both side of center keelson at specific distance running from steam to stern on the bottom plate which is the longitudinal bending this plate is called side keelson. It may be T or L section.

16. Mention the use of center girder of a ship =A continuous member running from aft to forward at the under the deck plate is called center girder. Use of center girder:- (a)Support of the deck plate & beam (b) Support the pillar widely spaced (c) Reduce the longitudinal bending,(d) Increase the longitudinal strength.

17. Mention the use of side girder of a ship=A continuous member running from aft to forward at the both side center line under the deck is called side girder.

18. Describe frame of a ship=A vertical continuous member holding the outside plating in shape and maintaining the transverse from the ship is called frame. The frame is connected by bracket with beam & supported in the side stringer.

19. Describe the necessity of different frames in shipbuilding=Frame is one kind of structure. Ship construction is depends of frame. If (it is used shell structure/frame is used to the shell structure). There are two kinds of kinds frame use of the ship body construction. These are transverse frame and longitudinal frame. Without it use of various type of frame.

20. Mention the use of opening in the shell plating of a ship = The use of opening in the shell plating are given the bellow:- (a) Entre the air (b) To remove the gas(c) To remove the sound(d) To remove the dangerous water.

21. Describe the function of beam in ship with mid ship supper structure =Beam is a one kind of beck structure .Beam is used deck of the ship. Beam is used hold to the shell & deck plating. Functions of the beam is given to the bellow:- (a) To remove the side water pressure (b) To remove the deck stram (c) It increase the deck strength

22. Mention the functions of hatch beam=Beam function are given the bellow (a) To support the hatch cover (b) To strength the hatch coaming (c)To remove the bending stress.

23. Describe the function of beam in ship with mid ship super structure= Beam is one kind of deck structural. Beam is used deck of the ship. Beam is used hold to the shell & deck plating .the function the beam is given to the below:-(a) To remove the side water pressure(b)To remove the deck strain(c) Its is use deck strength.

24. Identify side & end chocks= A heavy smooth surfaced fitting usually located near the edge of the weather deck through which wire ropes or fiver hawse may be laid down or raised this is chocks.

25. Mention the tools, equipment & materials used in hull layout=

There are many kinds tools used in hull layout such as,=Tools:-welding machine ,cutter ,hammer ,measuring tools etc. Equipment:- rolling machine ,bending machine .

Slipway, Material handling equipment, Cutting & shaping m/c , Milling & drilling m/c

26 Frame erection system:- This is an old practice adopted for wooden ship in many years ago and adopted for iron, steel ship of riveted construction in the 19th century. The process of frame erection system is as follows:-

1. Keel laying

2. Assembly

3. Completion of bottom shell plate.

4. Fitting of double bottom plating.

5. Assembly of inner bottom plating.

6. Completion of double bottom.

7. Fitting of side frame.

8. Completion of frame erection.

9. Assembly of side shell plating.

10. Fitting of deck beam, girder and pillar.

11. Fitting of deck plating &

12. Completion of cargo hole.

27. Block assembly system: The block assembly system is adopted by almost all shipyard today. Hull construction is divided many parts depending on the crane capacity of the shipyard and each block is fabricated independently. The blocks are position in the building berth and welded. The process of block assembly system is as follows:-

1. Assembly of double bottom block.

2. Completion of bottom construction.

3. Shell plating.

4. Completion of side shell block.

5. Deck plating

6. 6.Completion deck blocks &

7. 7. Block joints.

*Keel :-the keel runs along the from aft to forward center line aft the bottom plating at the ship which is after said to from the back bone at the ship. It is removed the longitudinal bending.

*Stem:- The stem is the terminating point of the shell plate .mild steel

*Stem plate: these plates which are covered the stem bar is specific breadth extend from the deck to keel.

*Stern:- The stern is the termination point of aft at shell plate.

Why used of stem plate:- (a)Increase vertical strength of the forward (b)Remove the panting

*Bar stem:- Bar stem is solid round on rectangular bar. Its consist of forged steel /cast steel. It is fitted from the keel to the upper must deck.

b=1.32L+84 in mm

t=0.53L+9in mm

where L= length of the ship in meter .

.jpg/r%5Bwidth%5D=1920/Dam8NZsTT8Kgc17jBt0F_three-typical-hull-shapes-displacement-semi-displacement-planing%20(1).jpg)

No comments:

Post a Comment